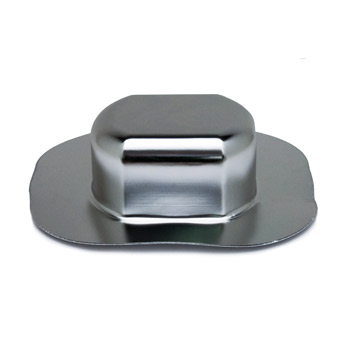

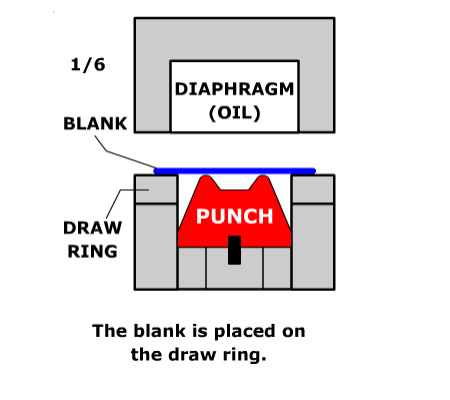

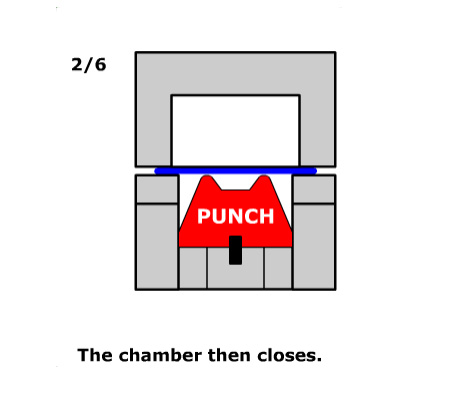

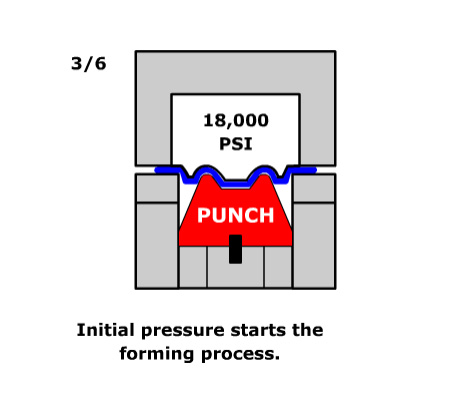

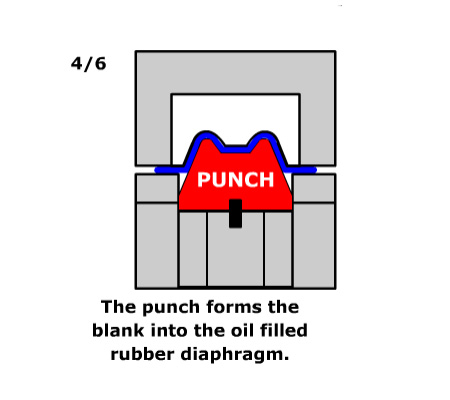

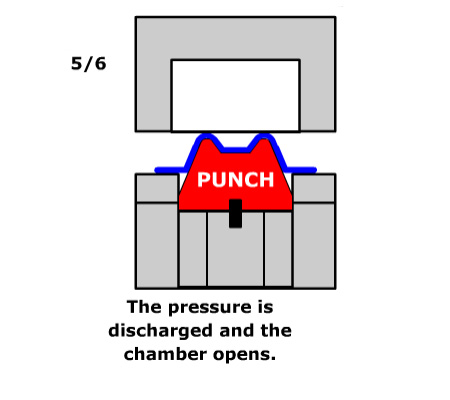

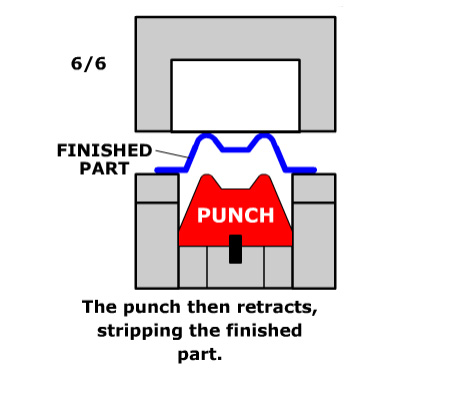

Bladder Hydroforming

Bladder Hydroforming is very similar to stamping, except that a rubber diaphragm backed by 18,000 psi of oil acts as the mating half to the punch. This reduces the cost of tooling by half, since only one die is required. We have several Cincinnati Bladder-Type Hydroform Machines at our facility, ranging from 8″ to 32″.

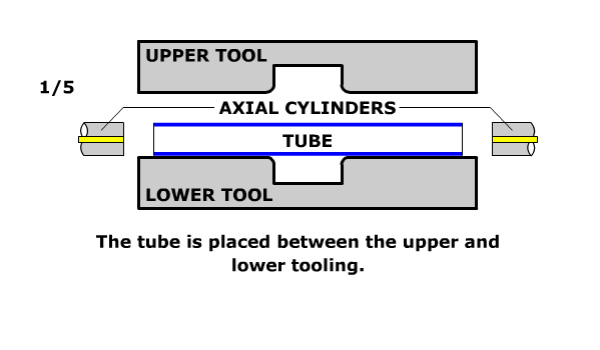

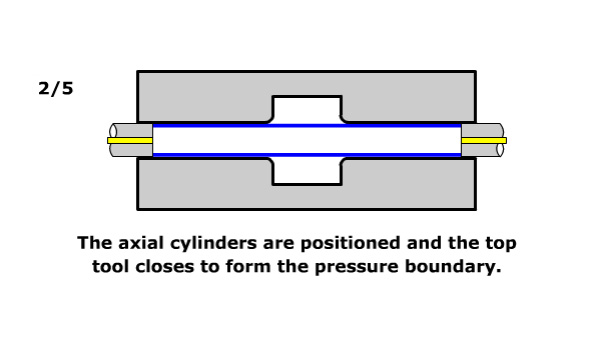

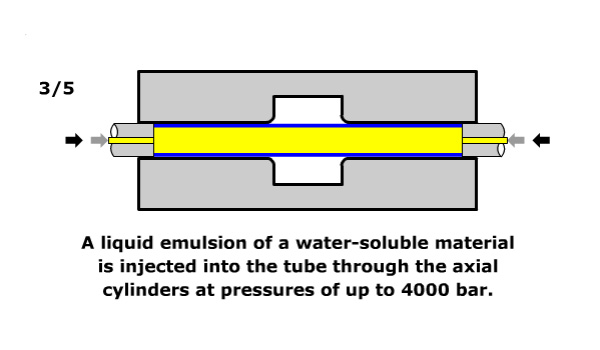

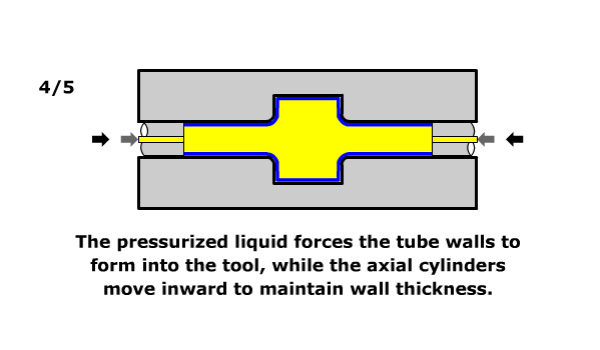

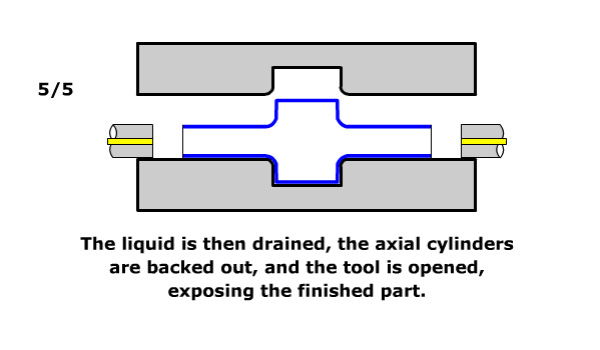

Tubular Hydroforming

Tubular Hydroforming is gaining popularity in several markets for its track record of producing better quality components at a lower cost. Some of the benefits of Tubular Hydroforming over conventional tubular structure forming and welding include:

Our automated AP&T Tubular Hydroforming unit uses state of the art controllers, is rated at 1200 tons with pressures of up to 4000 bar and can handle part lengths of up to 42 inches.

- High Precision maintaining constant wall thickness

- Piercing during the HF process

- Complex parts produced with less tooling expense

- Increased product design flexibility and part strength

- Lower weight because of less material used

- High bending strength and torsional stiffness

- Increased overall quality and structural intent

The UHI Group is standing by to add value to your manufacturing process. Contact us today to learn more about our hydroforming capabilities and find the perfect solution for your needs.